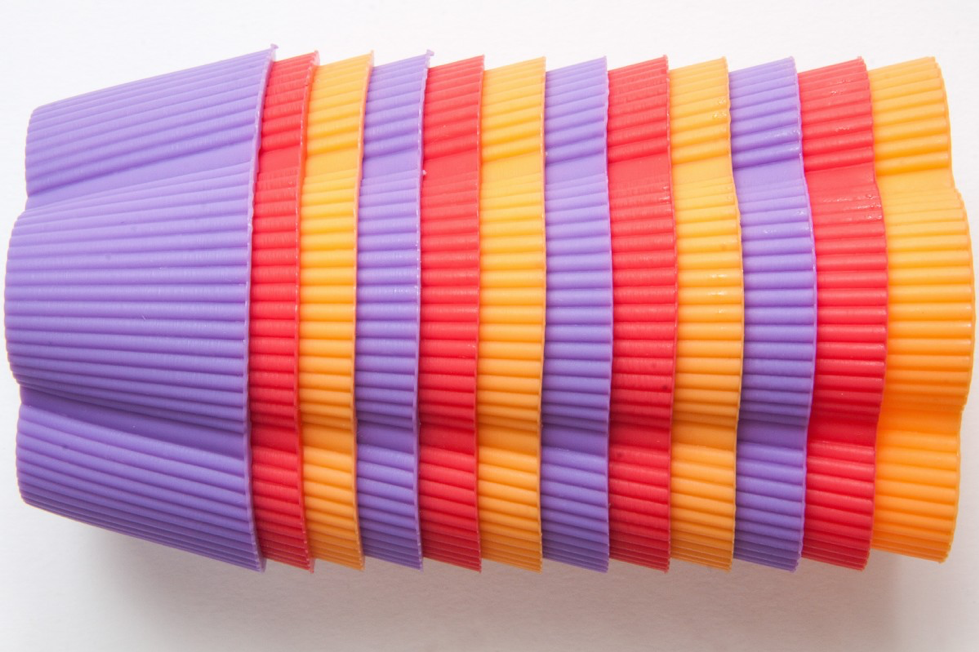

Plastic extrusion is the process of creating plastic profiles and tubes by forcing melted plastic through a die. The process is used to create a wide range of products and component parts that are utilised for both industrial and domestic purposes. Due to the need to force these plastics into a shape, thermoplastics will be used, as they are the best type of material for melting down and cooling to form a rigid shape. Polypropylene and PVC are two of the most commonly used thermoplastics for plastic extrusion purposes. In this blog post, we take a look at a few ways in which plastic extrusion can be used.

Continue reading “What Can Be Made Using Plastic Extrusion?”