One of the most commonly used materials for plastic tube extrusion is polypropylene. In this article, we take a look at why polypropylene is used for plastic extrusion purposes and what can be made from it.

What is Polypropylene?

Polypropylene (PP) is a very versatile plastic and is chosen as a material for plastic extrusion due to its low cost, high-temperature tolerance and durability. Depending on its intended use, there are varying grades of polypropylene, making it suitable for a range of applications, from food packaging to automotive components.

Why is Polypropylene Used For Tube Extrusion?

There are a number of reasons why polypropylene is the best material to use for plastic extrusion.

Heat Resistance

Firstly, in comparison to other plastics, polypropylene is fairly resistant to heat. Offering a higher melting point, polypropylene is the perfect choice for creating items which require heat resistance, such as electrical components or for use in transferring hot liquids or gasses.

Chemical Resistance

Polypropylene is also resistant to many chemicals, particularly those which are acidic or alkaline, making it a great tubing choice for labs and industrial uses. Polypropylene tubes are also typically strong enough to be protected against corrosion.

Stress Resistance

Even under heavy torsion, bending or stress, polypropylene can maintain its shape well, regardless of the number of uses. This makes it a great material choice for plastic hinges, such as those used on caps for squeezy bottles or plastic box cases.

Customisable

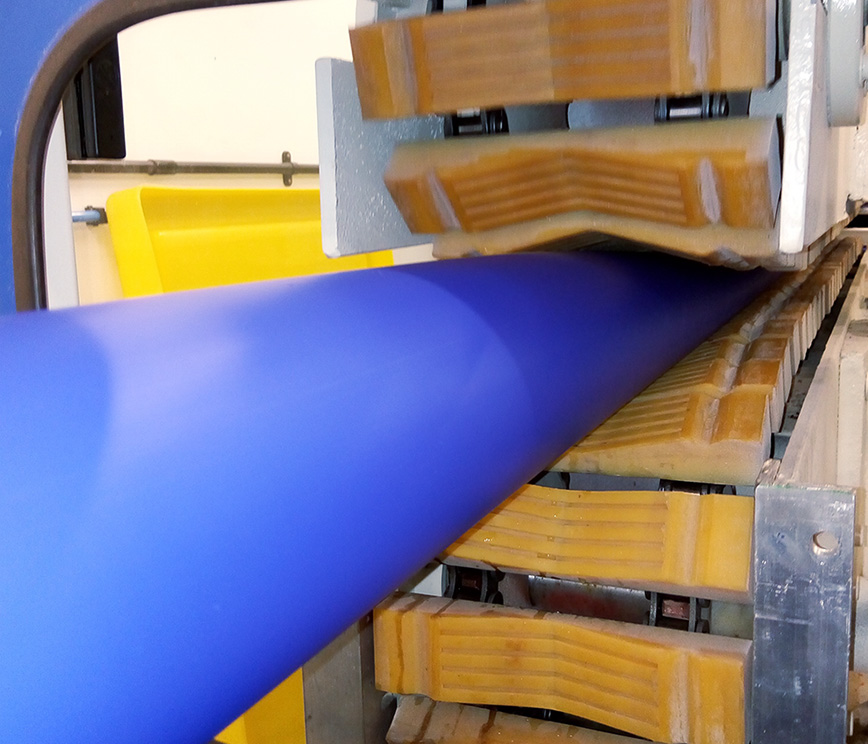

Polypropylene also offers a highly customisable material, as tubes can be created in solid colours, multiple colours, translucent or clear depending on the intended use.

Economical

Polypropylene offers a wide variety of applications for a relatively cheap price, as one of the lower cost plastic options for extrusion. As well as this, polypropylene plastics are widely recyclable, allowing the materials to be reused, furthering its cost efficiency.

What is Polypropylene Tube Extrusion Used For?

Tube extrusion of polypropylene plastics offers a very diverse range of uses, and profiles or tubes can be custom created based on a customer’s needs. Amongst many other products, polypropylene tubing could be used as components for cars, parts of windows or doors, agricultural equipment, parts of toys and food grade tubing.

There are two main grades of polypropylene used for plastic extrusion products; homo-polymer and co-polymer. Polypropylene Homo-polymers are more commonly used, and this offers a strong and stiff plastic that can be welded, allowing it to be incorporated into many structures. It also offers good chemical and corrosion resistant properties. The other frequently used type, Polypropylene Co-polymer is slightly softer than polypropylene homo-polymers, yet it tends to be tougher and more durable, offering better impact strength and stress resistance, making it more suitable for uses at lower temperatures than other polypropylene materials.

If you think polypropylene tube extrusion could help to create the product you require, then your business is sure to benefit from our polypropylene extrusion services. To find the right plastic extrusion solution for you, do not hesitate to contact us today, as one of our expert team will be more than happy to help! If you would like to learn more about the plastic extrusion process, then check out our recent blog post What Is Plastic Extrusion?